Efficient Bag Sealing for Diverse Packaging Needs #

Continuous bag sealing machines are engineered to meet the demands of high-volume packaging environments. These machines are ideal for sealing thermoplastic materials such as polyethylene, plastic-lined, foil, and gusseted bags, regardless of their size or length. With adjustable operating speeds, the equipment ensures consistent performance without causing wear to the sealer, making it a reliable choice for various industries.

A key feature of these machines is the variable speed conveyor belt, which can be raised, lowered, or angled to accommodate different package types. By integrating a semi-automatic packing sealer into your workflow, packaging time can be significantly reduced, effectively increasing productivity.

For more information or to discuss your specific requirements, please reach out to your trusted packing equipment suppliers.

Product Range #

Vacuum Sealer Machine (HIPPO)

Vacuum Sealer Machine (HIPPO)

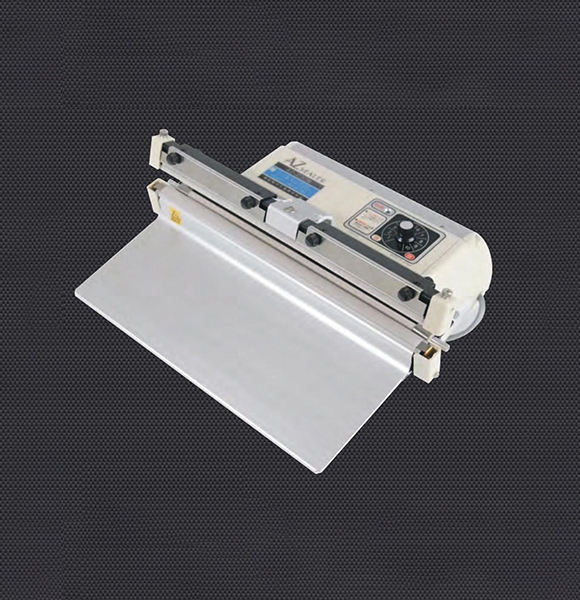

Impulse Sealer (AZ-300W)

Impulse Sealer (AZ-300W)

Ultrasonic Point Sealer (QUPPA)

Ultrasonic Point Sealer (QUPPA)

Tabletop Band Sealer Machine (TD-c53)

Tabletop Band Sealer Machine (TD-c53)

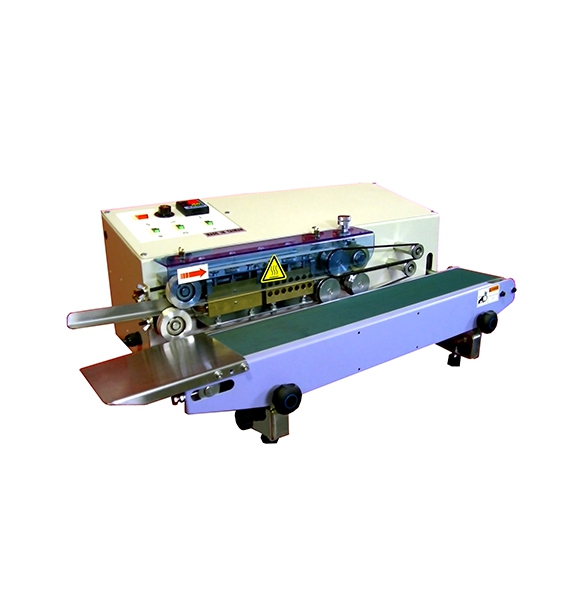

Horizontal Band Sealer (TD-c103)

Horizontal Band Sealer (TD-c103)

Vertical Band Sealer (TD-c120)

Vertical Band Sealer (TD-c120)

Key Features and Applications #

- Vacuum Sealer Machine (HIPPO): Features a detachable nozzle for easy cleaning.

- Impulse Sealer (AZ-300W): Offers strong, compact sealing with simple hand pressure.

- Ultrasonic Point Sealer (QUPPA): Enhances food safety, provides easy-to-open packaging, and presents products attractively.

- Tabletop Band Sealer Machine (TD-c53): Suitable for sealing bags containing food, chemicals, or hardware; compatible with any heat-sealable material.

- Horizontal Band Sealer (TD-c103): Equipped with four wheel spinners for smooth mobility and stable sealing quality.

- Vertical Band Sealer (TD-c120): Designed for stand-up pouch bags and suitable for sealing liquid or powder-filled bags.

These solutions are tailored to support a wide range of packaging applications, ensuring efficiency and reliability in your production line.