Discovering Horizontal Flow Wrapping for Modern Packaging #

Horizontal flow wrapping machines have become an essential part of efficient packaging lines across various industries. Designed to streamline the process of feeding, wrapping, and sealing products, these machines offer a reliable solution for both food and non-food items, ensuring consistent and protective packaging.

Key Advantages of Horizontal Flow Wrappers #

- Efficiency: Streamline your packaging process with quick and accurate product handling.

- Versatility: Suitable for a broad spectrum of products, from snacks and bakery goods to personal care and industrial items.

- Durability: Constructed with high-quality materials for long-lasting performance.

- Custom Solutions: Machines can be tailored to meet specific packaging requirements.

- Lifetime Support: Ongoing service and support are available for the lifetime of the equipment.

Product Range #

A variety of horizontal flow wrapper models are available to accommodate different product sizes and industry needs. Below are some featured options:

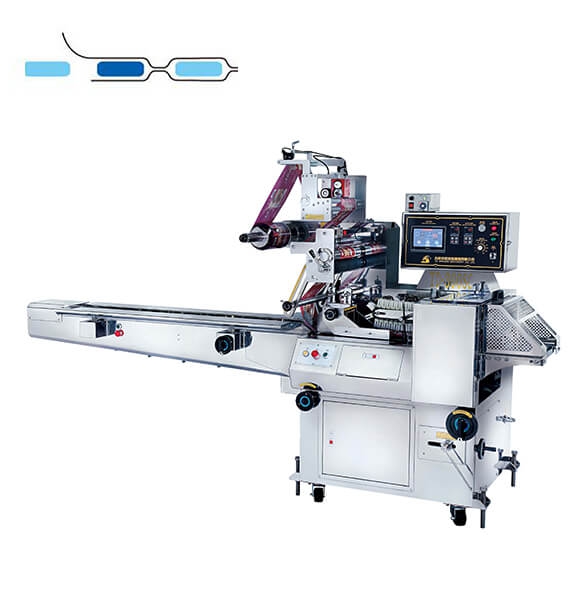

TD-200C Horizontal Flow Wrapper

TD-200C Horizontal Flow Wrapper

TD-200SC Horizontal Flow Wrapper

TD-200SC Horizontal Flow Wrapper

TD-200SCG Horizontal Flow Wrapper

TD-200SCG Horizontal Flow Wrapper

TD-300C/TD-400C/TD-500C Horizontal Flow Wrapper

TD-300C/TD-400C/TD-500C Horizontal Flow Wrapper

TD-300SC/TD-400SC/TD-500SC Horizontal Flow Wrapper

TD-300SC/TD-400SC/TD-500SC Horizontal Flow Wrapper

TD-300SCG/TD-400SCG/TD-500SCG Horizontal Flow Wrapper

TD-300SCG/TD-400SCG/TD-500SCG Horizontal Flow Wrapper

Example Product Specifications #

- TD-200C: Min. Product Size: L40×W15×H3(mm), Max. Product Size: L150×W100×H40(mm)

- TD-200SC / TD-200SCG: Same size range as above

- TD-300C/TD-400C/TD-500C: Ideal for non-food solid products, all contact parts in stainless steel

- TD-300SC/TD-400SC/TD-500SC: Designed for food products, with stainless steel or food-grade plastics

- TD-300SCG/TD-400SCG/TD-500SCG: Food sector focus, easy maintenance, no special tools required

How Horizontal Flow Wrappers Operate #

The process begins with an in-feed conveyor that spaces products into a forming box. The machine then wraps heat-sealable film around each item, seals the film, and cuts it to create individual bags. This method protects products from contamination and helps extend shelf life.

Typical Applications #

Horizontal flow wrappers are widely used in:

- Food products: frozen items, snacks, bakery goods

- Personal care products

- Household items

- Industrial and automotive parts

- Medical and pharmaceutical supplies

Customization is available to meet specific packaging needs across these sectors.

Frequently Asked Questions #

Q: What is a horizontal flow wrapper?

A: Horizontal flow wrapping is a packaging process that forms bags from a single roll of film in a horizontal orientation. Both ends of the film are sealed using hot or cold sealing technologies, resulting in secure pouches. This method is adaptable for a wide range of product sizes and is suitable for both food and non-food applications.

Q: What is HFFS?

A: Horizontal Form-Fill-Seal (HFFS) equipment forms, fills, and seals pouches or flow wraps in a single continuous motion. The packaging material moves horizontally, integrating all steps for greater efficiency and flexibility in packaging formats.

Q: How does a horizontal flow wrapper work and what is the maximum production speed?

A: The machine creates bags from a single roll of film, sealing both ends to form secure pouches. It is suitable for a variety of products, including cookies, bakery goods, snacks, and medical devices. The process is efficient and adaptable, enhancing product presentation and shelf life.

Q: What are the most important requirements for cleaning and sanitation in horizontal flow wrap machines?

A: Easy accessibility and clear visibility of machine components are crucial for effective cleaning and sanitation. Machines should allow for quick disassembly and reassembly of belts, rollers, and scrapers, especially for parts in contact with product residue. All contact components should be removable without tools to maintain high hygiene standards.

For further details or to discuss tailored solutions, contact Tai Dragon Machinery.